Safetrack® PinBrazing – All-weather installations! Quick & safe!

Safetrack® patented Pin Brazing system quickly create safe, electrical cable connections to steel structures without melting the steel base material as welding methods do. The secret behind the patented system is a specially developed silver-based alloy that melts (650ºC) through a strictly controlled energy distribution from powerful batteries through our self-developed, patented and automated Brazing Gun.

Safetrack® PinBrazing is used in many industries to connect cables and is particularly suitable for use in the cathodic protection industry for connecting cables to pipelines, ships, rebar, etc.

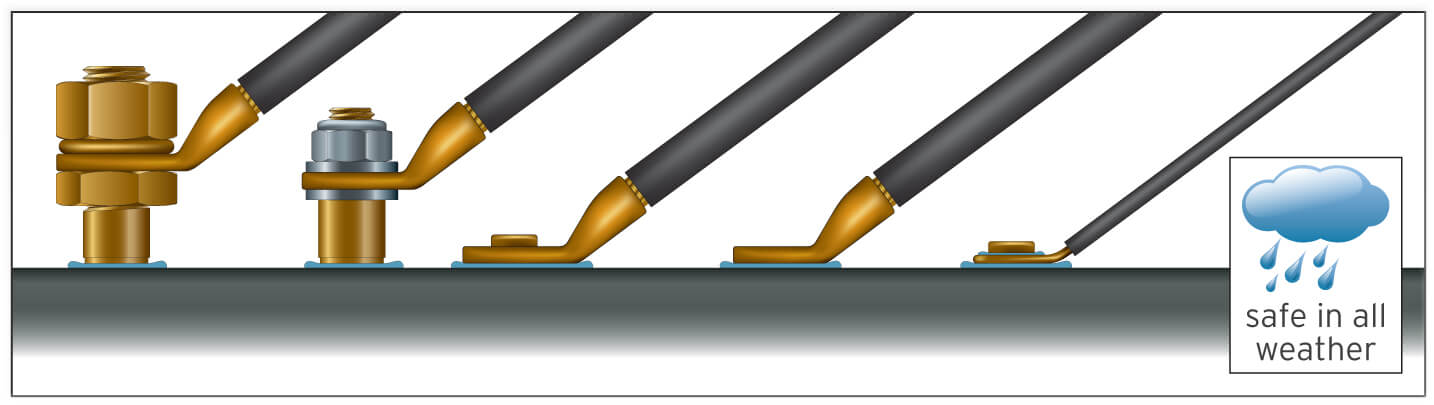

With Safetracks® patented, electronic, battery-powered PinBrazing system, you make installations quickly and safely, in all weathers, at any time - rain and snow are no longer a problem. No risk to the operator.

Safetrack® PinBrazing - Invented, developed and manufactured in Sweden

- Instant process: Each PinBrazing connection takes just one second, and the entire procedure is done in minutes.

- Low heat: The low-temperature silver alloy protects internal coatings and surface integrity.

- Material-safe: Unlike exothermic welding, no melting or damage occurs to the base material – only a thin silver layer bonds cable and steel.

- All-weather operation: Works flawlessly in rain, snow or wind.

- Ideal for offshore use: Perfect for pipe-laying barges – no molds, no waiting.

- Operator-safe: Battery-powered 36VDC system, free from hazardous materials or open flames.

- Superior conductivity: The silver alloy ensures strong molecular bonding and ultra-low transition resistance.

- Fully automated: Just pull the trigger – the precision-controlled, 1-second automatic process delivers a perfect bond every time.

Download the Brochure

More on PinBrazing

When a Cathodic Protection system is applied to a pipeline with spigot and sleeve joints, these joints must be electrically bonded. PinBrazing is used to ensure a safe electrical connection to different types of steel structures.

For Pipelaying vessels it is very important to connect the bracelet anodes to off-shore pipes fast and safe, both in a horizontal and vertical position. PinBrazing has all these advantages compare to thermite welding or other welding methods; PinBrazing is easy and fast to use also on vertical surfaces, can be made in any weather conditions, does not melt the steel down in the pipe (which is not very popular among the infrastructure owners), PinBrazing just melts a layer of silver between the cable from the anode to the pipe which also gives the best electrical properties to the bonding.

When attaching the Jumper Bonds over the joints, the

patented SAFETRACK PinBrazing can be used.

When you need the very best (silver) connection of your

Cathodic Protection cables to steel, ductile or cast-iron pipe, vessel, tanks or reinforcement bars.

No more confusion and maintenance with thermit weld molds and weld portions. Just Pin Braze your cables, easy and quick!

SAFETRACK Electronic PinBrazing method is approved by GAZPROM, Russia.

Pin Brazers worldwide

Safetrack patented Pin Brazing system is in use in over 85 countries worldwide.

Some of Safetracks Pin Brazing customers:

Cathodic Protection Industry

Gazprom, Russia. Corrpro, USA. Sydgas, Sweden, Savcor Art, Finland. Eesti gaas, Estonia. Stolt Offshore, USA. Pipeline integrity management, Israel. Corrosion Controlo Services, India. PSL, India. Petunia Co, Iran. Iranian Offshore & engeneering Co IOEC, Iran. Saipem, Kazakhstan. Bitco, Kuwait. RWNA, Malaysia. BSS Technologies, UAE. Euramco, UK. Gaskomplekt OAO Beltransgaz, Belarus. Corrpol, Poland. Toyo Engineering, Japan. Shell, Malaysia.

Rail Industry

Burlington Northern Santa Fe RailRoad, USA. Union Pacific RailRoad, USA. Canadian National Railway, Canada. Canadian Pacific Railway, Canada. Russian Railways, Russia. West.Ter, Russia. Network rail, UK. Banverket (Swedish Railway). Stockholm Underground, Sweden. Strukton Rail, Sweden. Gothenburg Tramway, Sweden. Balfour Beatty, Sweden. VR (Finnish state railway). Helsinki Metro, Finland. Siemens, Germany. Alstom, France. Algerian Railway, Algeria. Indian Railways, India. Sterling Transtel, India. Egyptian National Railways. Lithuanian Railways. Izmir Metro, Turkey. Greece State Railway.

FAQ - Frequently Asked Questions about PinBrazing

1. What is the economic benefit by using PinBrazing for pipelines?

- It works in all weather. Even in rain and snow. No risk for the operator.

- It does not melt the steel in the pipe with the cables, it melts only the silver alloy.

- Quick and automatic process. About 2 minutes in total for a cpl. bonding. 1. Grinding of surface 2. Press the gun button. 3. Ready! Since the method is so fast the total cost stays very low.

- Does not require any special knowledge of the operator.

- Can store units & consumables for several years without taking damage. No special requirement for storing

- Low temperature, does not damage the coating on the inside of the pipeline.

2. Who is the manufacturer and supplier?

- Safetrack manufactures all the material (equipment, consumables), which ensures an optimum result.

3. What is the power source at the pinbrazing unit?

- Battery. No other power source is needed for operation. After about 50 solderings the unit is charged with the charger powered by 230/110 V AC. Also the grinding machine is powered by the battery in the unit. 4. Is preheating of the pipelines needed?

- No. There is no need to preheat with this method.

- Melting temperature for the solder material itself is only about 650°C(1200°F), the surface is heated up to this temperature and is reached after only 1 second. Unlike thermite welding which is an exothermic process (more energy gets out than what is put in) provides extreme temperatures of thousand degrees and even melts the steel down.

- With the pin brazing one can touch with the finger on the brazing area only a few seconds after the brazing process.

5. Should one clean the surface from flux after the soldering?

- No cleaning is necessary since the contact surfaces has a molecular bindning between the cable lug and the pipeline.

6. Where can I buy the PinBrazing system?

- You can contact us directly, either we have a distributor near you or we supply directly to you. Safetrack PinBrazing is used in more than 85 countries worldwide today.