Safetrack® PinBrazing System – Reliable Electrical Bonding for railways

The Safetrack® PinBrazing System is a unique, patented and battery-driven brazing method for applying electrical connectors to steel structures such as railway rails, pipelines, tanks, ships, and offshore installations. It is widely used for signal, power, return, and grounding bonds within the railway sector, and with great advantage in cathodic protection (CP) systems.

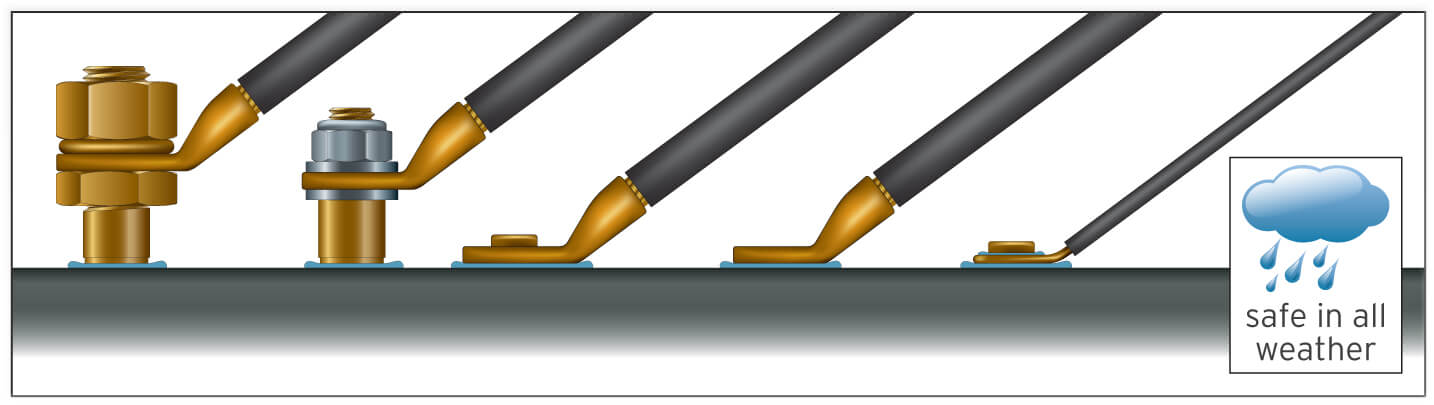

The secret behind the patented system lies in a special silver-based alloy developed by Safetrack. This alloy, with a melting point of 650°C (1200°F), is melted by a precisely controlled energy pulse from high-power batteries through Safetrack’s patented, electronic, and fully automated brazing device. The silver alloy forms a strong metallic bond between the cable strands and the steel surface – ensuring extremely low contact resistance, mechanical durability, and long-term corrosion protection.

Unlike welding, PinBrazing does not melt or alter the base material, meaning there is no metallurgical impact on the steel structure. This makes the Safetrack® method both safe and efficient, with quick installation times and minimal equipment requirements.

Key Advantages

- Low temperature: Only the silver alloy melts (650°C / 1200°F).

- Safe for the material: A true silver brazing method – does not melt the base metal like welding.

- All-weather operation: Works flawlessly in rain, snow, or cold environments.

- Fast & efficient: The brazing process takes just one second; total preparation less than a minute.

- Enables rail break detection: Attach rail bonds on the side of the rail head instead of drilling holes.

- Cost-effective: Low consumable cost and minimal maintenance.

- Safe for the operator: Battery-powered and fully automated.

- Corrosion-free bonds: Reliable and long-lasting electrical connections.

- No molds or external power needed.

- Lightweight & portable: Compact, battery-operated 36V DC equipment.

Download PinBrazing Brochure

Pin Brazers worldwide

Some of Safetracks PinBrazing customers:

Rail Industry

Burlington Northern Santa Fe RailRoad, USA. Union Pacific RailRoad, USA. Canadian National Railway, Canada. Canadian Pacific Railway, Canada. Russian Railways, Russia. West.Ter, Russia. Network rail, UK. Trafikverket (Swedish Railway). Stockholm Underground, Sweden. Strukton Rail, Sweden. Gothenburg Tramway, Sweden. Balfour Beatty, Sweden. VR (Finnish state railway). Helsinki Metro, Finland. Siemens, Germany. Alstom, France. Algerian Railway, Algeria. Indian Railways, India. Sterling Transtel, India. Egyptian National Railways. Lithuanian Railways. Izmir Metro, Turkey. Greece State Railway. Polish Railways.

Cathodic Protection Industry

Corrpro, USA. Korrosionsgruppen, Sweden. Sydgas, Sweden, Savcor Art, Finland. Eesti gaas, Estonia. Stolt Offshore, USA. Pipeline integrity management, Israel. Corrosion Controlo Services, India. PSL, India. Petunia Co, Iran. Iranian Offshore & engeneering Co IOEC, Iran. Saipem, Kazakhstan. Bitco, Kuwait. RWNA, Malaysia. BSS Technologies, UAE. Euramco, UK., Poland. Toyo Engineering, Japan. Shell, Malaysia.